Aerox-Injector

The Aerox-Injector is an innovative odor control system based on our invented cold plasma injection technology that is installed at the end of a chimney. Already more than 250 plants around the world benefit from our proven effective technology.

State-of-the-art

Aerox developed the Aerox Injector in collaboration with universities and research centers. And this has been tested from the beginning with one of our customers. Our injection technology is based on cold plasma. Clean outside air is fed through specially developed cold plasma modules. As a result, the air becomes agitated and reactive. Also called active oxygen, this gas mixture enters into a very rapid oxidation reaction at the injection point with the odor components in the process air. This solves the odor problem because people cannot smell the oxidized odor particles.

Easy maintenance

An Aerox® injector requires maintenance only once every 10,000 hours. Production can continue as usual while the maintenance is being carried out. The system operates completely autonomously and continues to do its job optimally for 10,000 hours. The modular design allows for flexible expansions and upgrades. As a plant owner, you are assured of state-of-the-art technology with additional benefits such as:

- Optimal odor reduction

- Minimal use of electricity

- No water, gas or chemicals required. No waste

- Easy to install, even in existing plants

- Suitable for any temperature and humidity

- Only 1 maintenance cycle per year, no production downtime

- Low total cost of ownership

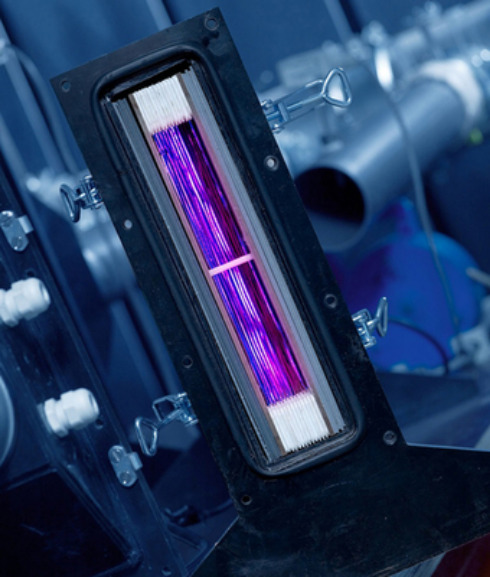

Cold plasma technology

The Aerox-Injector works on the basis of cold plasma, a sustainable and effective technology for minimizing odor emissions to combat odor nuisance.

What is plasma?

Plasma is also known as the fourth state of aggregation, in addition to liquid, solid and gas. Plasma is actually an ionized gas. Ionization is a process in which an atom loses one or more electrons and becomes positively charged. When enough atoms are ionized to noticeably change the electrical character of a gas, it is called plasma. Plasma conducts electricity, responds to changes in electric and magnetic fields and can accelerate chemical reactions.

Sustainable odor control

Aerox has developed plasma modules that generate cold plasma using electricity. Through cold plasma, odor particles can be oxidized as early as room temperature. The Aerox Injector therefore requires relatively little electricity, making it a sustainable and cost-effective technology. It does not generate a significant temperature rise in the process air stream.

The plasma modules convert clean air into an agitated and reactive gas mixture, also called active oxygen. This reactive gas is then injected into the pipe with the process off-gases to oxidize the odor components present.

The injection principle

The Aerox-Injector uses filtered outside air to combat odor problems. The clean air is injected – after processing – into the outgoing process gases.

Reactive gas mixture

The outside air is first passed through a triple filter. The filtered clean air is then blown into the Aerox injector, where it passes through a series of cold-plasma modules. The plasma splits the oxygen and water vapor molecules. Now a reactive gas mixture is created: “active oxygen. This highly reactive gas is then injected into the process pipe or stack.

Odor reduction through oxidation

The reactive particles in the injected air oxidize very quickly (< 0.5 seconds) with the odor components in the exhaust gases. This makes them impossible for the human nose to smell. The odor problem is solved.

Insulated plasma field

There is no direct contact between the off-gases from the process and the plasma field. The injection fan ensures that the pressure in the Aerox-Injector is always higher than in the chimney, preventing exhaust gas from entering the system. Thereby, the specially designed injection adapter between the Aerox-Injector and the process channel is equipped with check valves.

Installing odor reduction system

The Aerox injector takes up little space. In fact, it needs to convert very little air into cold plasma to handle large volumes of air (up to 250,000 m3/h per Aerox injector). Thanks to injection technology, the system is easy to integrate into the production process. There is no need to shut down production and no major modifications to existing facilities.

Certifications

Aerox has safety as a top priority. That’s why we can provide our systems according to various certifications.

ATEX

ATEX, an abbreviation for “Atmosphere Explosible,” comprises the European standards for explosion safety. This lists all situations where there is a risk of explosion hazard from gases. If you want to place (electrical) equipment in Europe in areas where explosive gases may occur, you must have the machine certified to ATEX standards.

In other parts of the world, IECEx standards are used for explosion protection. IECEx standards are practically the same as ATEX when it comes to machine certification. The main difference is that each country has different ways in which IECEx standards are implemented, while ATEX standards are implemented the same way throughout the European Union.

UL (Underwriters Laboratories) / CSA (Canadian Standards Association)

For the delivery of our systems in America, we can produce our systems according to the UL standard. This seal of approval focuses on (fire) safety for humans, animals and the environment.

To supply our systems in Canada, we can produce our systems to CSA standards. The seal is a sign of quality and safety and is also recognized in the United States.

CE

All our systems that we supply have a CE mark. The CE mark indicates that the Aerox injector meets all EU safety, health and environmental protection requirements.

More about our technology?

Further development

With more than 25 years of experience in cold plasma injection technology, Aerox has gained a lot of experience and incorporated it into our Aerox injectors. Consequently, our products are spread all over the world, including some that are still extremely active in odor control after 20 years.

Sustainability

The Aerox-Injector is the most durable industrial odor reduction solution. Specifically designed in view of the environment and the possibility of recycling almost all parts. All an Aerox injector needs is a little bit of energy.